Messung Automation Solutions for Water and Waste Water Projects

The Rising Demand

By year 2050, the global demand for water will rise by 55%. The 2015 report by United Nations World Water Development projects this rise across the various sectors.

India’s economy also critically depends on use and management of water for agriculture, industry and domestic consumption. Recognizing this dependence, the Ministry of Water Resources plans to invest significant funds into management of water and wastewater sector.

Some of the aims of good water resources management are:

- Improvement of water quality

- Improving energy efficiency while managing and treating water

- Minimizing leakage and wastage

- Conservation of resources

- Reducing downtime and operating costs

Use of dedicated Automated Control Systems effectively meets the above objectives, at a cost-effective price point.

Infrastructure for Water Treatment

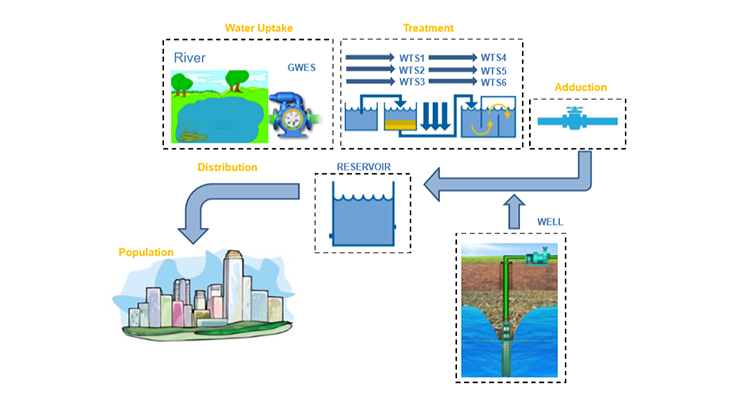

To supply quality water in the desired quantities, a typical city may have more than 20 to 30 Water Treatment Plants (WTP’s). At the discharge end, for treating used and polluted water, the city may have an equal number of Waste Water Treatment Plants (WWTP’s).

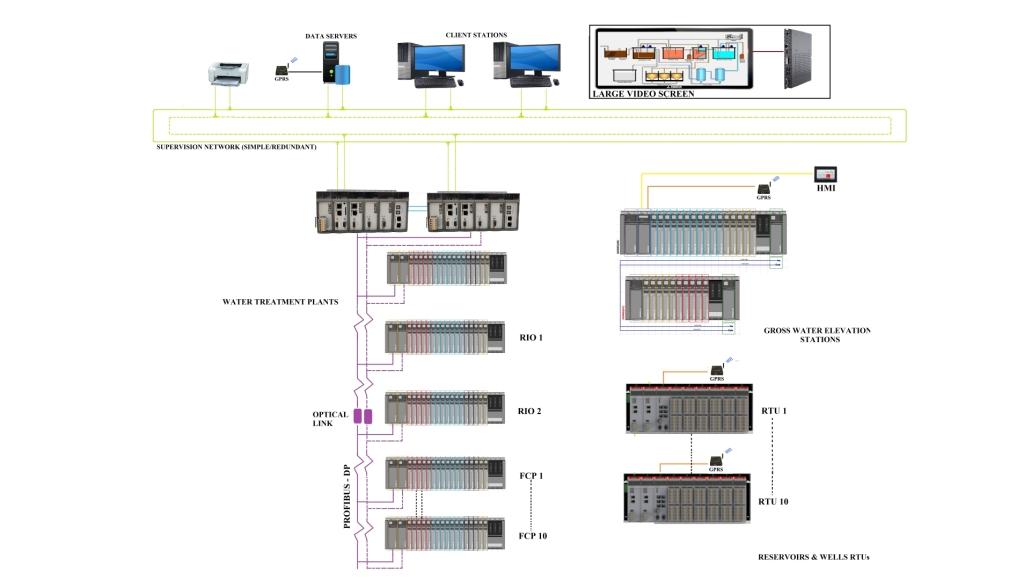

For optimum efficiency and speed of response, a Centralized Control and Monitoring Station supervises all the equipment and processes of plants from a single location. This Station accepts numerous inputs from all the plants to deliver real-time corrective responses to the changing parameter and conditions. As an upgrade, tech-savvy Municipal authorities now demand a cloud-based solution for supervision of all the water treatment facilities.

High-technology automation solutions conforming to industry standard protocols are essential to implement the future needs of the water treatment plants.

Challenges of Water Supply System

Designing and operating of water supply systems calls for a multi-criteria approach. In every case, water treatment system must reliably produce quality water at the lowest possible costs.

The criteria for water treatment process are:

- Flow of raw and treated water along with dosing of treatment chemicals

- Monitoring of water pressure at upstream and downstream locations and at critical points

- Monitoring levels in rivers, wells and reservoirs

- Disposal of sludge

- Monitoring of temperature for motors, bearings and valves

- Dosing of Fluorine, Chlorine and Calcium

- Monitoring turbidity and water quality

Water Treatment domain consists of several critical processes that can benefit from high technology automation for delivering consistent results.

Water Treatment Automation Solutions from Messung

Messung are the pioneers of Indian automation domain. With over 3 decades of domain expertise, tens of thousands of Messung Programmable Logic Controllers (PLC) and allied products meet the automation challenges of Indian industries, under actual local site conditions.

With a view to the future, Messung now offers NX-ERA, the complete industrial automation solution for monitoring and controlling the entire water management process.

Messung’s NX-ERA PLC Systems can automate a variety of Water Treatment applications.

These include:

- Water Treatment Plant

- Reverse Osmosis Plant

- Demineralized Water Plant

- Sewage Treatment Plant

- Effluent Treatment Plant

- Pumping Stations

- Reservoir Controls

Features of Messung NX-ERA

- One vendor – many solutions

- Easy to set-up, maintain, operate

- Compatible with all industry standard protocols

- Highly reliable system with high Mean Time Between Failures (MTBF) and low Mean Time to Repair (MTTR), with redundancy

- Local and remote access, with control to private mesh

- Local Human-Machine Interfaces (HMI’s) and Central Supervisory System

- Uses Open Protocols and Networks

- Power efficient with a small footprint

- Adds Distributed Control System (DCS) functionality through multiprocessing capability

- Can operate large numbers of remote Input/Output (I/O) points and backplane racks for implementing distributed architecture with redundancy

- Supports large screen displays and database server

- Interfaces with Supervisory Control and Data Acquisition (SCADA) systems

- Modular and expandable

Programming through the IEC 61131-3 compliant MasterTool IEC XE software.

- Easy to learn with rich graphics and intuitive textual language

- Function Block Diagram (FBD) that enables segmentation of block system to simplify maintenance and simultaneous execution of different tasks

- Multiple languages available within these blocks for versatility across the globe

Conclusion

Messung’s NX-ERA process control solutions optimize complex control for water treatment and distribution systems. These solutions help implement highly efficient WTP designs that help treat and conserve water, an increasingly scarce resource.

The water-scarce future mandates a high degree of precision and reliability of water treatment plants. Messung’s process control and automation solutions effectively meet the monitoring and control requirements of water treatment with increased plant safety and availability.